Sublimation vs. Heat Transfer: A Guide for Custom Textile Businesses

At their core, the two most popular methods for custom decoration come down to one simple difference: sublimation embeds dye into the fabric, while heat transfer lays a design on top of it.

This one distinction changes everything. It dictates the final feel, how long the design will last, and even what kinds of products you can create. Sublimation gives you a permanent, incredibly soft print that you literally can't feel. Heat transfer, on the other hand, is the more versatile workhorse but adds a tangible layer to the surface of the item.

A Quick Guide To Sublimation Vs Heat Transfer

Choosing your decoration method is a foundational decision for any custom apparel or gift business. It directly affects your startup costs, your day-to-day workflow, and—most critically—the quality of the products you hand over to your customers. Getting to know the real differences between sublimation and heat transfer vinyl (HTV) is the first step in turning premium blanks into profitable, in-demand items.

For small print shop owners, Etsy sellers, and custom gift businesses, this isn't just a technical choice. It's about finding the right process to bring your creative vision to life.

Key Takeaway: The real question isn't which method is "better." It's about which one is the right tool for the specific job. A photo-realistic design on a fleece blanket calls for a completely different approach than a bold, single-color logo on a cotton t-shirt.

To get you started, let's quickly break down the most important differences at a high level. This quick comparison will give you a solid foundation before we dig deeper into the nuances of each process.

Sublimation Vs Heat Transfer At A Glance

This table gives you a quick snapshot of how these two methods stack up, helping you make a fast initial assessment of which one might fit your needs.

| Attribute | Sublimation Printing | Heat Transfer (HTV) | Best For... |

|---|---|---|---|

| Feel / Hand | Zero texture. The dye is infused directly into the fabric fibers, so the material feels exactly as it did before printing. | A noticeable layer. The design sits on top of the fabric, which you can feel. The texture can range from smooth to slightly rubbery. | Premium, soft-to-the-touch items like our Mink Touch or Sherpa blankets where feel is everything. |

| Durability | Permanent. Because the design becomes part of the polyester, it absolutely will not crack, peel, or fade, no matter how many times it's washed. | Good to Excellent. High-quality HTV is very durable, but over time and with many washes, it can eventually crack, peel, or fade. | Full-color, permanent designs on polyester items that need to hold up to heavy use and washing, like towels or apparel. |

| Fabric Type | Polyester-based. You need light-colored fabrics with a high polyester count (ideally 100%) for the dye to bond and show up vibrantly. | Highly versatile. Works on almost anything—cotton, polyester, blends, and more. It also works on any color, light or dark. | Printing on a huge variety of materials, especially 100% cotton garments or dark-colored fabrics where sublimation isn't an option. |

| Color & Detail | Photographic quality. It can produce millions of colors, handling complex gradients, fine details, and photorealistic images with ease. | Vibrant but limited. Best for solid colors and simpler graphics. More complex designs mean you have to physically cut and layer different colors of vinyl. | Stunning, full-color photos, intricate patterns, and edge-to-edge designs on our sublimation-ready blankets and towels. |

Ultimately, understanding these core attributes helps you match the method to the material and the desired outcome.

A Look at the Core Printing Processes

Before you can really get into the sublimation vs. heat transfer debate, you have to understand what’s happening on a molecular level. Both methods use a heat press to get a design onto a fabric, but that's where the similarities end. The way they work is completely different, and those differences are what define the look, feel, and durability of the final product.

How Sublimation Becomes One with the Fabric

Sublimation is really a bit of a chemistry experiment. It starts with special solid inks that, when you heat them up to around 400°F, skip the liquid phase entirely and turn straight into a gas.

This gas gets into the very pores of polyester fibers, which open up under the heat. As everything cools down, the gas turns back into a solid, but now it's trapped inside the polymer strands. Your design isn’t just sitting on top; it’s literally become part of the textile.

Key Insight: This molecular bond is why sublimated designs have zero "hand"—you can't feel the print at all. It's fused into the fabric, not sitting on top of it. This makes it the only real choice for products like our premium fleece and sherpa blankets, where softness is the whole point.

This dyeing process is also why sublimation is so incredibly durable. The design can't crack, peel, or fade because it's not a layer that can be damaged. It will last as long as the fabric itself.

How Heat Transfer Sits on Top of the Fabric

Heat transfer, which you probably know from heat transfer vinyl (HTV), is much more straightforward—it’s all about adhesion. Instead of becoming part of the fabric, you're basically applying a thin, flexible layer of material onto its surface.

You’ll cut your design from a sheet of vinyl, weed out the bits you don't need, and then use a heat press to activate a special adhesive on the back of the vinyl. That adhesive melts just enough to create a strong bond, sticking the design firmly onto the garment.

Think of it as a high-tech, super-durable sticker made for fabric. It sits on the surface, which is why you can always feel the texture of the design. We break down the materials involved in our guide to different types of heat transfer printer paper.

Why This Difference is Crucial for Your Business

The market numbers tell a compelling story. The global dye sublimation printing market hit an impressive USD 14.9 billion in 2024. It’s also growing faster than other heat transfer methods, with a projected 11.3% CAGR through 2030. The reason? Its incredible efficiency on polyester blends, which are perfect for products like our rugged 410 GSM Outdoor Picnic Blankets with their soft, micro-plush tops.

Knowing the nuts and bolts of each process is essential for anyone running a printing business.

- Sublimation is your go-to for premium, full-color, permanent designs that feel incredibly soft. The trade-off is that you're limited to light-colored, high-polyester fabrics.

- Heat Transfer is the versatile workhorse. It works on almost any fabric and color, including cotton, but it adds a physical layer to the product and the longevity can vary, especially with complex designs.

Here at Spark Blank Textiles, we specialize in high-quality, sublimation-ready blanks. We’re big believers in the permanent, vibrant, and professional finish it delivers for premium gifts and home decor. Our curated selection of textiles is chosen specifically for makers who compete on quality.

A Detailed Comparison Of Key Performance Factors

When you're deciding between sublimation and heat transfer, you're making a choice that goes way beyond the final look. This decision shapes everything from your product's lifespan and how it feels in a customer's hands to how efficiently you can run your production line. Let's get past the basic pros and cons and dig into the five factors that really matter when you're growing a print business.

Durability And Washability

The longevity of a print is a direct reflection of your brand’s quality, and this is where sublimation truly shines. Because the ink becomes a permanent part of the polyester fibers, the design will never crack, peel, or fade. It doesn’t matter how many times it goes through the wash; the print lasts as long as the fabric itself.

Heat transfer vinyl (HTV), on the other hand, relies on an adhesive bond to stick to the fabric. While a high-quality application can certainly withstand dozens of washes, it's still a layer sitting on top of the material. Over time, with repeated stretching and washing, that adhesive can degrade, which is when you start to see cracking or peeling.

Business Insight: For premium items like photo blankets or custom towels that are meant to last for years, sublimation gives you—and your customer—unmatched peace of mind. That permanence justifies a higher price point because the quality is something you can see and feel for the life of the product.

Feel And Finish

How a product feels—what we call its "hand"—is a critical, and often overlooked, mark of quality. Sublimation delivers a zero-hand finish, which is a huge deal. Since the dye is infused directly into the fabric, the printed area feels completely identical to the unprinted material. This is absolutely essential for products where softness is the main selling point.

Think about a customer receiving one of our cozy Sherpa Sublimation Throws. They're expecting plush comfort, and a sublimated design gives them exactly that, without any stiff or plastic-like patch ruining the feel.

In contrast, heat transfer always adds a tangible layer on top of the fabric. The texture can range from smooth and thin to thick and slightly rubbery, depending on the type of vinyl you use. While this is perfectly fine for many applications like team jerseys or promotional bags, it fundamentally changes the original feel of the textile.

Color Vibrancy And Detail

When it comes to reproducing complex, full-color images with stunning detail, sublimation is in a league of its own. The process can create millions of colors and blend gradients seamlessly, giving you true photographic quality. This makes it the only real choice for detailed portraits, intricate patterns, or vibrant landscapes on products like our Woven Tapestry Blanks.

Heat transfer vinyl is much better suited for bold, solid-color graphics. Designs are made by cutting shapes from pre-colored sheets of vinyl. While you can layer different colors for a multi-color image, the process quickly becomes cumbersome, not to mention it adds bulk. It simply can't replicate the fine detail and smooth color transitions you get with sublimation.

The market data backs this up. In 2023, sublimation technology claimed a commanding 47.2% share of the global heat transfer paper market, a clear sign that businesses are shifting toward superior color technology. This growth explains why more and more businesses are choosing sublimation-ready blanks, like our 430 GSM Sherpa and 300 GSM Fleece Throws, to deliver the vibrant, fade-proof prints their customers demand.

Material Compatibility

This is the one area where heat transfer holds a decisive advantage. HTV's adhesive-based system works on a massive range of materials, making it incredibly versatile.

- 100% Cotton: The go-to fabric for most apparel.

- Polyester & Poly-Blends: Works well across various synthetic fabrics.

- Leather & Wood: Can be applied to certain non-textile hard goods.

- Light & Dark Colors: Opaque vinyl shows up perfectly on any color background.

Sublimation, however, is a specialist. It has two strict chemical requirements: a high-polyester content (ideally 100% polyester) and a light-colored surface. The dye only bonds with synthetic polymers, not natural fibers like cotton. And because the ink is transparent, it won't be visible on dark fabrics. This is precisely why we at Spark Blank Textiles focus on curating premium, high-polyester textiles—they are engineered from the ground up to produce the absolute best sublimation results. If you want to dive deeper, check out our guide on selecting the right printers for heat transfer paper.

Production Speed And Scalability

Figuring out the "faster" method really depends on the specific job you're doing.

For a simple, one-off custom item with a single-color design, heat transfer is often quicker. You can cut, weed, and press a basic logo in just a few minutes without waiting for a printer.

However, when you're dealing with complex, multi-color designs or large batch orders, sublimation pulls way ahead. With HTV, every additional color requires you to cut, weed, and press a separate layer, which dramatically increases your labor time. With sublimation, you print the entire full-color design in one shot and press it in a single step. Printing ten intricate photo blankets is far more efficient with sublimation than trying to layer all that detail with vinyl.

Head-To-Head Feature Analysis

To make things even clearer, let's break down how these two methods stack up against each other across the most important metrics for your business.

| Feature | Sublimation | Heat Transfer | Spark Textiles Recommendation |

|---|---|---|---|

| Durability | Permanent. Becomes part of the fabric; will not crack, peel, or fade. | Good to excellent. A layer on top of the fabric; can degrade over time. | For premium, long-lasting products like blankets and heirloom items, sublimation is the only way to go. |

| Feel (Hand) | Zero feel. The printed area is indistinguishable from the raw fabric. | Noticeable layer. The feel can range from thin and smooth to thick. | When softness is a key selling point (e.g., fleece throws, baby items), the zero-hand finish of sublimation is essential. |

| Color & Detail | Photographic quality. Unlimited colors, gradients, and fine details. | Best for solid colors. Limited by the colors of vinyl available. | For complex, full-color images or photos, sublimation is unmatched. Use HTV for bold logos and text. |

| Material Compatibility | Limited. Requires light-colored, high-polyester content fabrics. | Highly versatile. Works on cotton, poly, blends, leather, and wood. | HTV is the clear winner for cotton apparel and dark garments. Our polyester blanks are specifically designed for superior sublimation. |

| Production Speed | Fast for batches and complex designs. A single print and press cycle. | Fast for simple, one-off jobs. Labor-intensive for multi-color designs. | For scaling production of vibrant, detailed designs, sublimation is far more efficient. For quick, simple jobs, HTV is faster. |

Ultimately, this table shows there’s no single "best" method—just the right method for a specific product and business goal. By understanding these nuances, you can align your decoration technique with the quality and experience you want to provide for your customers.

A Look at Startup Costs and Material Investments

Deciding between sublimation and heat transfer goes way beyond the creative process—it's a critical financial decision that can define the trajectory of your business. To build a realistic budget and map out your path to profit, you have to get a firm grip on both the initial investment and the ongoing material costs.

Let's break down what it really takes to get started with each method.

The upfront cost is usually the first thing people look at. While both processes use a heat press, the other big-ticket items are quite different, and that's where the numbers start to diverge.

Key Insight: Sublimation might have a steeper price tag to get in the door, but its per-print cost for detailed, full-color designs is often much lower than layering multiple colors of HTV. This makes it a powerhouse for scaling up a business that specializes in photographic images or complex graphics.

Thinking about long-term success means looking past that initial receipt. You need to consider how material costs will chip away at your profit margins on every single order you fulfill.

The Financial Breakdown for Sublimation

Jumping into sublimation requires a specialized, purpose-built setup. You can't just repurpose a standard inkjet printer from your office—the science behind the ink is entirely different.

Here’s what you’ll be investing in:

- A Dedicated Sublimation Printer: This is your starting point and it's non-negotiable. It needs to be a machine built for or professionally converted to handle sublimation inks.

- Sublimation-Specific Inks: These aren't just colored liquids; they're special dyes designed to transform from a solid into a gas when heated.

- A Quality Heat Press: This is the heart of your operation. It provides the consistent, even heat and pressure required for the dye infusion to happen.

- Sublimation Release Paper: This is the temporary home for your printed design before it's pressed onto your blank.

If you're just starting out, our complete guide on building the right dye sublimation kits is a great resource for making those initial choices. Once you're set up, your main ongoing costs are just ink and paper. For full-color prints, this is often far more cost-effective than stocking and cutting multiple colors of vinyl.

The Financial Breakdown for Heat Transfer

Getting started with heat transfer, especially with heat transfer vinyl (HTV), can feel a bit more approachable from a cost perspective. The main equipment is focused on cutting your designs, not printing them.

Your main startup costs for an HTV business include:

- A Vinyl Cutter: This machine is what you'll use to precisely cut your designs from sheets or rolls of vinyl.

- A Heat Press: Here's the one major piece of equipment you'd need for either method.

- Weeding Tools: Don't underestimate these! They're small, essential hand tools for picking out the excess vinyl from your cut design.

- Heat Transfer Vinyl (HTV): You'll need to build an inventory of vinyl rolls in all the colors and finishes your customers might want.

The initial price for a cutter and some tools is often lower than a complete sublimation system. The catch? Your ongoing material costs are directly tied to how complex your designs are. If you want to create a multi-color graphic, you're buying, cutting, and carefully layering several different colors of vinyl. This can drive up both your material expenses and the time it takes to produce each item.

The market trends tell a compelling story about where the industry is heading. The global market for sublimation equipment is projected to swell from US$2.7 billion in 2025 to US$4.1 billion by 2032, easily eclipsing the flat sales of traditional heat presses. This growth is fueled by shops and makers who are prioritizing durability. After all, a sublimated print keeps about 95% of its color vibrancy after 100 washes, while HTV can fade to just 70%. As more small businesses aim to capture a piece of this massive market growth, investing in high-quality sublimation blanks right now is a smart move for the future. You can dive deeper into these numbers in this detailed business analysis of sublimation machine trends.

When Should You Use Sublimation?

It's one thing to understand the theory behind sublimation and heat transfer, but it's another thing entirely to know exactly when to use one over the other to create a product people will actually want to buy. This is where your choice of blank is just as critical as your printing method.

Sublimation is your go-to when the goal is premium quality. Think photographic detail, vibrant colors, and a luxurious, soft feel. You're not just putting a design on a product; you're creating a high-end item that commands a higher price.

Let's break down the specific products and scenarios where sublimation isn't just a good choice—it's the only choice for getting that professional, top-shelf result.

For Plush Blankets Where Softness is Everything

Take our flagship products: the Sherpa, Fleece, and Mink Touch blankets. People buy these for one reason above all else: comfort. The absolute last thing a customer wants is a stiff, plastic-like design ruining the cozy feel of their new throw. This is precisely where sublimation shines.

Because the sublimation process infuses dye directly into the polyester fibers, the finished print has absolutely zero feel or "hand." The blanket is just as soft and touchable after you press it as it was before.

- Photo Blankets: Nothing captures the detail and subtle color shifts of a photo collage or a memorial piece like sublimation. It’s simply unmatched.

- High-End Keepsakes: The permanence and soft finish turn a simple blanket into a treasured gift for weddings, anniversaries, or a new baby.

- Boutique Home Goods: If you're building a brand around premium home decor, you need designs that won't crack or peel. Sublimation ensures your quality and reputation last.

Expert Insight: At Spark Blank Textiles, our blanket collection was built for this. Their 100% polyester makeup isn't just a random spec—it's the key that unlocks those brilliant, permanent, and impossibly soft prints you just can't get with heat transfer vinyl.

For Seamless, Edge-to-Edge Designs

Ever seen a beach towel with a stunning landscape that stretches from corner to corner? Or a picnic blanket covered in a vibrant, seamless pattern? That’s the magic of sublimation at work.

Trying to pull off a large, full-coverage design with HTV would be a practical nightmare. You'd be patching together massive sheets of vinyl, leaving you with a final product that’s heavy, stiff, and prone to cracking along the seams. It just doesn't work.

Sublimation, on the other hand, was made for this. You can print one giant transfer and press it onto products like our Beach Towels or Outdoor Picnic Blankets. The design becomes a flawless part of the fabric itself, keeping the towel absorbent and the blanket flexible without adding any weight or texture.

This makes it perfect for:

- Branded Promotional Gear: Imagine a golf towel with a company's logo printed in a full-bleed, eye-catching design for a corporate tournament.

- Artist Merchandise: Turn a blank woven tapestry into a sellable piece of art by printing an artist's work across the entire surface.

- Personalized Decor: Create custom picnic blankets that are as beautiful as they are functional and durable.

Ultimately, choosing sublimation is a business decision. It signals a commitment to quality, durability, and a better customer experience. When you match this powerful process with a blank that's engineered for it—like the ones we offer at Spark—you’re set up to create a product that not only stands out but also builds a reputation for excellence.

Making The Right Choice For Your Business Goals

The whole sublimation versus heat transfer debate isn't about which one is "best." It's about finding the right tool for the job—and for your brand. The method you choose will ripple through every part of your business, from your daily workflow to what your customers feel when they unbox their order. To make a smart call, you have to start with a clear picture of what you want to create.

Are you building a brand around high-end, keepsake-quality gifts? Do you want a reputation for breathtaking, full-color photo products that feel incredibly soft and command a premium price? If that's you, then sublimation isn’t just an option; it's the core of your entire business model.

Questions To Guide Your Decision

Thinking through these questions will get you on the right track, moving you past the technical specs and into how this choice affects your business in the real world.

- Who are you selling to? Are they after budget-friendly shirts for a team event, or are they buying a one-of-a-kind photo blanket meant to last for decades?

- What are you actually making? Is your signature product a cozy sherpa throw where hand-feel is everything, or is it a simple cotton tote for a promotional giveaway?

- What makes your brand special? Are you known for bulletproof durability and stunning photo quality, or for your lightning-fast turnarounds and ability to print on almost anything?

- What does growth look like for you? Will you be scaling up by running large batches of intricate, colorful designs, or by handling quick jobs with simple, single-color graphics?

Your answers lay out the roadmap. A business that specializes in personalized keepsakes and high-end home decor is going to find its home with sublimation. On the other hand, a print shop that serves local events with all sorts of apparel needs the grab-and-go flexibility of heat transfer.

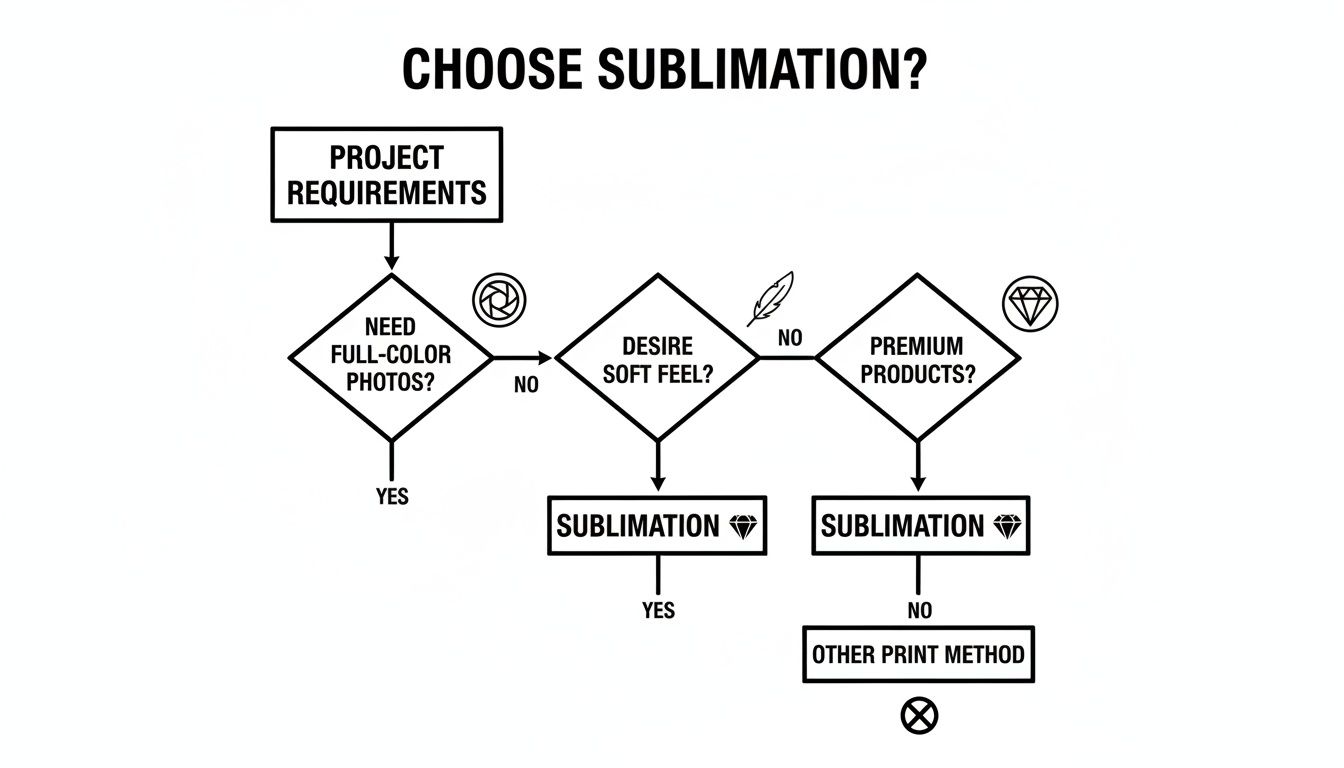

When Sublimation Is The Clear Winner

If your business is all about creating top-tier, premium products, the choice pretty much makes itself. This decision tree maps out the journey for any brand that puts quality first.

As you can see, for anyone focused on detailed photos, a "no-feel" finish, and products built to wow customers, sublimation is the only way to go. It's an investment, but it's one that pays off in quality.

Our Promise to You: This is the principle we've built Spark Blank Textiles on. We're not just selling blank goods; we're providing the high-quality foundation your business needs to succeed. We hand-pick our selection for creators who refuse to cut corners on feel, vibrancy, and longevity.

In the end, it comes down to matching your method to your mission. If your goal is to turn premium fabrics into vibrant, permanent works of art, sublimation is how you get there. It's more than just a printing technique; it's a commitment to a standard of excellence that will make your brand stand out.

Ready to create products that people will rave about? Explore our collection of premium, sublimation-ready blankets and towels and feel the difference that quality materials make.

Got Questions? We've Got Answers

Even with all the details, you probably still have a few questions rolling around in your head. It’s normal! Here are some of the most common ones we hear from makers and small business owners trying to choose between sublimation and heat transfer.

Can I Really Not Use Sublimation On a 100% Cotton or Black T-Shirt?

That's a firm no, and it all comes down to the science of the process. Sublimation isn't just ink sitting on top of a fabric; the ink turns into a gas and chemically bonds with polyester fibers. Natural materials like cotton just don't have the right molecular structure for that bond to happen.

Think of the ink as being translucent, too. If you tried to sublimate on a dark fabric, the design would simply disappear into the background. This is exactly why we at Spark Blank Textiles focus on high-polyester goods, like our fleece blankets, that are specifically designed to make sublimation colors pop. For any 100% cotton or dark-colored projects, heat transfer is definitely your go-to method.

Expert Tip: Don't see this as a limitation. See it as a strategic choice. By focusing on sublimation-ready materials, you're positioning your business to offer premium, durable products with a feel that you just can't get on cotton with other methods.

Which One Is Going to Make More Money for My Etsy Shop?

This really boils down to your brand and what you want to sell. You can build a very profitable business with heat transfer, especially if you're selling a high volume of items with simpler, text-based designs or one-color logos. The startup costs are lower, which is a huge plus when you're just getting started.

On the other hand, sublimation is where you can often find higher profit margins on individual items. It's the key to creating those "wow" products—think full-color photo blankets or intricate custom tapestries—that customers are willing to pay more for. While the equipment might cost more upfront, the actual cost per print for a complex, colorful design is often much lower than layering piece after piece of vinyl. If you want to be known for unique, heirloom-quality gifts, sublimation is your ticket.

Do I Seriously Need a Whole Separate Printer Just for Sublimation?

Yes, you 100% need a dedicated printer that has only ever had sublimation ink in it. You can't just swap cartridges in your regular office printer. Standard inkjet ink and sublimation ink are completely different chemical formulas, and even a tiny bit of cross-contamination will ruin your prints and your printer.

You've got two main paths here:

- Convert a new inkjet printer: Some models, like certain Epson EcoTanks, are popular for this. The key is to do it before a single drop of regular ink has been put in.

- Buy a purpose-built sublimation printer: Brands like Sawgrass build printers specifically for this from the ground up.

This is a non-negotiable part of your startup cost, so make sure to factor it into your budget when you're weighing sublimation vs. heat transfer.

At Spark Blank Textiles, we believe that the best products start with the best materials. Our curated collection of premium blankets and towels is thoughtfully chosen to give your sublimation projects the vibrant color and soft feel your customers deserve. Explore our full range of sublimation-ready blanks and start creating something brilliant.