A Maker's Guide to Finding the Perfect Heat Press Stand

A heat press stand isn't just a place to park your machine; it's the foundation of your entire print shop. Unlike a standard workbench, a purpose-built stand is specifically engineered to handle the unique demands of a heat press—its weight, the heat it radiates, and the consistent downward force you apply. The right stand is all about ensuring flawless transfers and a smoother, more professional workflow.

Why a Heat Press Stand Is Your Most Valuable Partner

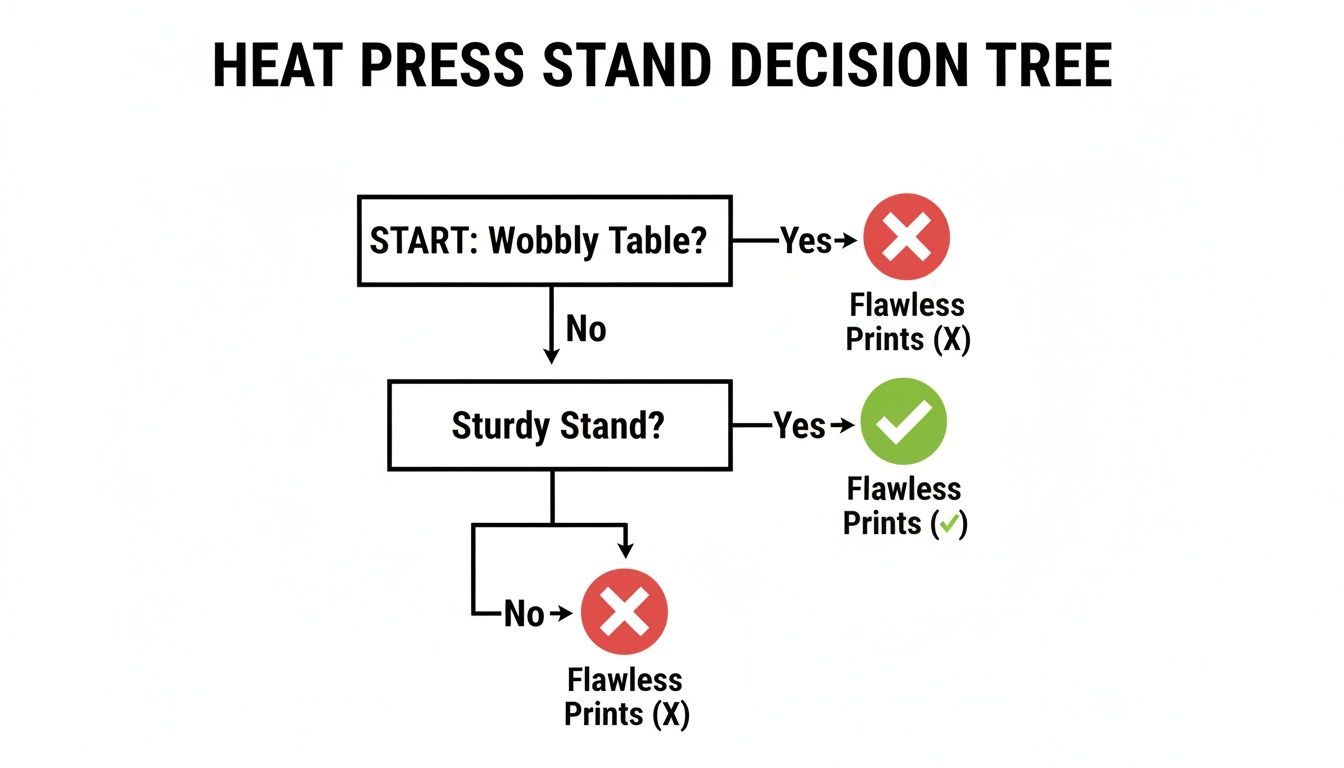

Let's be honest. That wobbly desk or old kitchen cart you're using just isn't cutting it for a growing business. When you’re pressing high-value items like our plush sherpa blankets or detailed woven tapestries, every detail matters. The slightest wobble can cause ghosting or uneven pressure, leading to wasted materials and lost profits—something no small business can afford.

Making the leap to a proper heat press stand is one of the smartest moves you can make. It's less of an accessory and more of a silent business partner, one that's completely dedicated to consistency and quality.

From Good Prints to Flawless Results

A truly sturdy stand eliminates the micro-movements that can ruin an otherwise perfect print. By providing a rock-solid base, you get the crisp, vibrant, edge-to-edge transfers your customers expect. For professional results, that kind of stability is absolutely non-negotiable.

This push for better equipment is a trend we're seeing across the industry. The global heat press market is expected to hit USD 1,315.39 million by 2032, largely because more creative entrepreneurs are realizing just how much a reliable setup matters for producing high-quality goods.

A dedicated stand transforms your workspace from a hobby corner into a professional production station. It's the unsung hero that supports every perfect print, saves your back during long production runs, and ultimately boosts the quality of everything you create.

By setting up an ergonomic and efficient pressing station, you’re not just making your work safer—you're making it faster. For more tips on getting those perfect results, check out our guide to the sublimation heat transfer process. At Spark Blank Textiles, we believe that building your business on the right foundation is what sets you up for long-term success.

Understanding the Three Main Types of Heat Press Stands

Picking the right heat press stand can feel like a big decision, but it really comes down to your space and workflow. Think of it like this: you wouldn't buy a massive commercial oven for a tiny home kitchen. The same logic applies here. You need the right foundation for your specific setup.

Let's break down the options into three main categories. Each one has its own set of perks, whether you're a maker working out of a spare bedroom or running a full-blown production shop. Knowing the difference will make choosing the right one much easier.

The first step to getting flawless, professional-looking prints is moving away from that wobbly dining room table to a dedicated, sturdy stand. It's a non-negotiable for quality.

As you can see, the stability of your setup directly impacts the quality of your work. That makes your stand a critical piece of business equipment, not just an accessory.

Carts and Mobile Stands

First up, we have carts and mobile stands. These are the versatile all-rounders of the heat press world. What makes them "mobile" are the heavy-duty casters (wheels) that let you move your entire pressing station around with ease. If your workspace has to wear multiple hats—design studio, production floor, and shipping station all in one—this kind of flexibility is a lifesaver.

The biggest win here is, of course, mobility. Need to clear the floor to pack a big order of custom blankets? Just unlock the wheels and roll the whole setup out of the way. Some of the best mobile stands even come with a "threadability" feature, which can speed up your workflow by as much as 40% by making it easier to load garments onto the press.

For anyone working in a multi-use space, the ability to reconfigure on the fly is everything. A mobile cart isn't just a stand; it's a tool that helps you get the most out of every square foot.

To help you quickly compare your options, here’s a look at how the different stand types stack up.

Heat Press Stand Types at a Glance

This table gives you a quick comparison of the main types of heat press stands to help you choose the best fit for your workspace and workflow.

| Stand Type | Best For | Key Advantage | Potential Drawback |

|---|---|---|---|

| Carts & Mobile Stands | Small shops, multi-use spaces, and home-based businesses. | Flexibility. Easily move and store your equipment as needed. | Can be less stable than fixed options if not locked properly. |

| Fixed & Bolt-Down Stands | High-volume production shops with a dedicated pressing area. | Maximum Stability. Eliminates all wobble for consistent pressure. | Not portable, making it a permanent fixture in your space. |

| Integrated & Specific Stands | Users of a specific high-end press model. | Perfect Fit. Guaranteed compatibility and seamless operation. | Often the most expensive and not interchangeable. |

Each type has its place, so the best one is simply the one that solves your biggest challenge—be it space, stability, or seamless integration.

Fixed and Bolt-Down Stands

Next, let's talk about fixed and bolt-down stands. Think of these as the unshakeable anchors of a serious production floor. These stands are built for one thing and one thing only: maximum stability. They typically don't have wheels and are constructed from heavy-gauge steel, with some even giving you the option to bolt them directly to the floor.

This is the go-to choice for established print shops or any business with a permanent, dedicated pressing station. Their rock-solid build gets rid of any swaying or wobbling, which is absolutely critical for achieving even, consistent pressure. This is especially true when you're working with large, premium items like our woven tapestry blankets. If your business depends on high volume and flawless consistency, a fixed stand provides the reliability you need.

Integrated and Machine-Specific Stands

Finally, we have integrated and machine-specific stands. These are the custom-tailored suits of the stand world. They are designed and built by heat press manufacturers to be the perfect companion for a specific machine model. You get a seamless fit, with pre-drilled holes that line up perfectly with your press’s base for a super secure connection.

While they're often the priciest option, the payoff is guaranteed compatibility. Everything is designed to work together, complementing features like an auto-open function or a specific swing-away motion. If you've already invested in a premium press, pairing it with its designated stand ensures you're getting the peak performance and safety the manufacturer intended.

Key Features That Separate a Good Stand From a Great One

Once you’ve figured out what type of stand you need, it's time to dig into the details that separate the good from the great. Not all steel frames are created equal. Getting this right means investing in a stand that will dramatically improve your workflow, keep you safe, and protect the quality of your products for years to come.

It’s a bit like buying a car. Two sedans might look similar on the outside, but you know the one with better suspension, a more responsive engine, and top-tier safety features will deliver a totally different driving experience. It's the exact same principle with heat press stands. The little things matter, especially when you're pressing premium textiles like our plush fleece blankets.

Let’s break down the five critical features to look for. Think of this as your personal checklist for finding a true workhorse, not just a temporary placeholder for your valuable equipment.

Weight Capacity and Build Quality

The first thing to check—and it's non-negotiable—is the stand’s weight capacity. Your heat press is a serious piece of machinery, often weighing between 50 and 100 pounds (or even more). It’s also top-heavy. Your stand must be rated to handle significantly more than your machine's weight to guarantee it won't buckle or tip under pressure.

Always, always look for stands built from heavy-gauge steel. This is not the place to cut corners. A flimsy frame will wobble every time you press, which is a one-way ticket to ghosted images and uneven pressure—the two biggest enemies of a perfect print. A solid build is the foundation for professional results.

Adjustability and Ergonomics

Long days spent pressing can be tough on your body. A stand with adjustable height is your best defense against the back and shoulder strain that sneaks up on you. For ideal ergonomics, you want the lower platen of your press to sit at or just below your elbow height. This lets you apply pressure naturally without hunching over.

A stand with adjustable height isn't a luxury; it's a core feature for any serious maker. It allows you to create a workspace that fits you, making your process more comfortable, efficient, and sustainable over the long term.

This kind of user-focused design is becoming the norm. In the specialized dye-sublimation market, which saw a whopping USD 921.3 million in heat press equipment sales, innovations that boost precision and safety are in high demand. Stands that can accommodate digital controls and auto-open functions are essential for small businesses striving for professional quality.

Mobility and Stability

For most small businesses and home-based makers, a workshop needs to be versatile. This is where locking casters (wheels) are a game-changer. They give you the best of both worlds: you can easily roll your press out of the way when you need the space, then lock it down securely when it’s time to work.

But let's be clear: the "locking" part is absolutely critical. The wheels need to be heavy-duty, and the locking mechanism has to be rock-solid. Before you start any pressing session, get in the habit of checking that every caster is locked. An unlocked stand is a major safety hazard, period.

The Right Footprint

Last but not least, you need to think about the stand's footprint. This means two things: the size of the top plate and its overall dimensions on the floor. First, the top plate has to be large enough to support the entire base of your heat press. No overhang. A press teetering on the edge of its stand is just an accident waiting to happen.

Second, measure your actual workspace. Make sure the stand will fit comfortably while leaving you enough room to move around it safely to grab your blanks and tools. This is especially important if you have a swing-away press, which needs extra clearance on the sides to operate. Planning your footprint properly makes your whole setup safer and much more productive.

Matching Your Stand to Your Press and Products

Finding the right stand isn't just about propping up a heavy piece of equipment. It’s about building a seamless workflow where your press, your products, and your creative vision all work together perfectly. When you get this match right, you set yourself up for consistent, professional-grade results on every single item.

First and foremost, the stand has to work with your specific heat press model. The three main styles—clamshell, swing-away, and draw—each move in very different ways, and that movement dictates the kind of support they need. A mismatch isn't just an inconvenience; it can ruin prints and even become a serious safety hazard.

Pairing Your Stand with Your Press Type

Think of your press and stand as a team that needs to be in sync. A clamshell press opens straight up, like a book, so it can often sit comfortably on a more compact stand. But a swing-away press is a whole different ballgame. Its top platen swings out horizontally, which dramatically shifts the machine’s center of gravity.

To handle that swing, the press needs a stand with a wider, more stable base to keep it from wobbling or, worse, tipping over. This isn't optional—it's essential for safe operation. Then you have the draw press, where the bottom platen slides out toward you. For this style, you need a stand that gives you clear, easy access from the front without anything getting in the way.

The right heat press stand does more than just hold the machine; it complements its specific motion. A stable, correctly paired stand ensures the press operates exactly as intended, providing even pressure and preventing accidents.

Aligning Your Setup with Your Products

Now, let's talk about the awesome things you’re making. The size and type of your products directly impact the kind of stability you need. If you're personalizing small golf towels, a sturdy mobile cart might be all you need. But if you're running production on large, premium textiles, your needs are much more demanding.

Imagine you're pressing one of our large fleece sublimation blankets. To get that perfect, edge-to-edge design with bold, vibrant colors, you need absolute stability on a perfectly level surface. The slightest wobble or tilt in your stand can cause uneven pressure, leading to faded spots or blurry transfers. That's a costly mistake on a high-value blank. Your stand is the silent partner ensuring the pressure you set is the pressure that gets delivered, evenly, across the entire garment.

This is why investing in the right heat press stands is so critical for any business focused on quality, just like us at Spark Blank Textiles. A rock-solid, level platform is your secret weapon for the flawless finish required for large-format products like picnic blankets and woven tapestries. If you're serious about getting those top-tier results, check out our guide to complete dye-sublimation kits to see how every piece of your setup plays a role.

How to Create a Safe and Efficient Pressing Station

Your heat press stand is the foundation, but a truly professional setup is more than just a piece of metal. Building an efficient and safe workspace means creating a system where every tool and supply has its place, letting you focus on what really matters: creating amazing custom products. This is how you turn a spare corner into a powerhouse production station.

Think of it like a chef's kitchen. Everything from spices to pans is strategically placed for a smooth, efficient workflow. Your pressing station should be no different. The goal is to minimize wasted movement and maximize safety, which is especially important when you're knocking out a big order.

Location and Electrical Safety

Picking the right spot for your heat press is your first big decision. You’ll want an area with great ventilation. Heat presses kick off a lot of heat and fumes, especially during sublimation, so an open window or a dedicated exhaust fan is non-negotiable for keeping your workspace comfortable and safe.

Just as crucial is your power source. Heat presses are thirsty for electricity, often pulling 10-15 amps or more. To avoid constantly tripping a breaker—or worse—you absolutely must plug your press into a dedicated circuit. Try to avoid extension cords. If you have no other choice, make sure it’s a heavy-duty cord rated to handle the high amperage your machine demands.

Ergonomics and Workflow Organization

Your long-term health is just as important as your output. Set your stand’s height so the lower platen sits at or just below your elbow. This simple ergonomic adjustment takes a ton of strain off your back and shoulders, letting you work comfortably and apply pressure correctly for hours on end. This is where an adjustable stand really shines.

Organize your materials to create a logical flow. We recommend keeping blank textiles—whether they're fleece blankets or beach towels—on one side and finished products on the other. This simple left-to-right (or right-to-left) process prevents mix-ups and keeps things moving smoothly. Have your essential tools like heat-resistant tape and protective paper right at your fingertips to shave precious seconds off every press.

A well-organized station does more than just look professional—it actively prevents costly errors. Innovations in automation and pressure control can cut user errors by up to 30%, but a stable, secure setup is the essential first step for consistent quality.

This kind of thoughtful setup is what separates the pros from the hobbyists in a market with over 20 million heat press units worldwide. A solid foundation is what allows you to get the precise, repeatable results that your customers will love.

Your Essential Safety Checklist

Before you start any pressing session, take 30 seconds to run through this quick checklist. It’s a habit that pays off.

- Secure the Press: Double-check that your heat press is bolted down tight to the stand. No wobbling!

- Lock the Casters: If your stand has wheels, make sure every single one is locked firmly in place.

- Clear the Area: Keep the space around your stand completely clear. Move any flammable materials or tripping hazards out of the way.

- Mind the Heat: Remember, the upper platen stays dangerously hot for a long time, even after you’ve shut the machine off. Always be aware of it.

Answering Your Heat Press Stand Questions

Even after you've done your research, a few common questions always pop up when it's time to choose a new heat press stand. Let's walk through them so you can feel confident you're making the right choice for your business.

Do I Really Need a Dedicated Stand for My Heat Press?

In a word, yes. It might be tempting to just use a sturdy table you already have, but a standard workbench isn't built for the unique demands of a heat press. Your press is heavy, top-heavy, and you're constantly applying downward force. A dedicated stand is specifically engineered to handle that load without the dangerous wobbling or tipping that can happen with a regular table.

Beyond safety, it’s about quality. A proper stand provides the rock-solid stability you need for consistent, even pressure. This is the secret to avoiding faded spots or blurry "ghosting" in your designs, especially on larger items. Think of it less as an expense and more as an essential investment in your safety and the quality of your work.

How Do I Know if a Stand Will Fit My Heat Press?

Figuring out compatibility is pretty straightforward. You just need to check three things: weight capacity, the size of the top plate, and the bolt pattern.

First, the easy one: make sure the stand's maximum weight limit is well above what your press actually weighs. Next, grab a tape measure. The base of your machine needs to fit completely on the stand's top surface with zero overhang. A press hanging off the edge is an accident waiting to happen.

Finally, look at the pre-drilled holes on the stand. If they line up with the mounting points on your press, you can bolt it down for ultimate security. Even if you're looking at a universal stand where the holes don't match, the most critical part is ensuring the platform itself is large and stable enough for your machine.

What Is the Best Height for a Heat Press Stand?

The right height is all about ergonomics—making sure you're comfortable and not straining yourself. The goal is to have the lower platen of your press sit at or just below your elbow height when you're standing naturally. This is the sweet spot.

This posture gives you the best leverage and control, which means less fatigue in your shoulders and back, especially when you're in the middle of a big batch of orders. It's the main reason adjustable-height stands are such a game-changer; they let you dial in the perfect height for your body.

Should My Heat Press Stand Have Wheels?

Wheels (or casters) can be a fantastic feature if your creative space pulls double duty. They make it a breeze to move your press out of the way for cleaning or to just switch up your layout. But there's a big "if" here: they have to be heavy-duty and come with reliable locking mechanisms.

You absolutely must lock the wheels every single time before you start pressing. An unlocked stand can shift unexpectedly, which is a major safety risk. If you're thinking of adding casters to a stand that doesn't have them, make sure they are specifically rated for the combined weight of the stand and your heavy press.

At Spark Blank Textiles, we know that a strong foundation is the start of any brilliant project. From our high-quality sublimation blankets to the stand that holds your press, every element plays a role in the final result.

Ready to bring your next idea to life? Explore our curated selection of premium blanks and get your project started on the right foot.